The Scanning Acoustic Microscope (SAM), as a new generation of scanning microscopes, is a very important non-destructive testing method. It has the advantages of high precision, non-contact, and being non-destructive. It can accurately display the internal structure of devices and locate the types and positions of defects without damaging or harming the inspected materials and parts. It is widely used in fields such as Quality Control (QC), Failure Analysis (FA), Reliability Analysis, Quality Control (QC), Quality Assurance and Reliability (QA/REL), and Research and Development (R&D).

Over the past few decades, the Scanning Acoustic Microscope has been developing towards the frontier directions of intelligence, automation, imaging, digitization, miniaturization, serialization, multi-functionality, and cross-fields. It has achieved non-destructive ultrasonic scanning microscopic imaging testing of complex surface composite components, meeting modern quality requirements for non-destructive testing. Next, let’s introduce the basic working principle of the Scanning Acoustic Microscope.

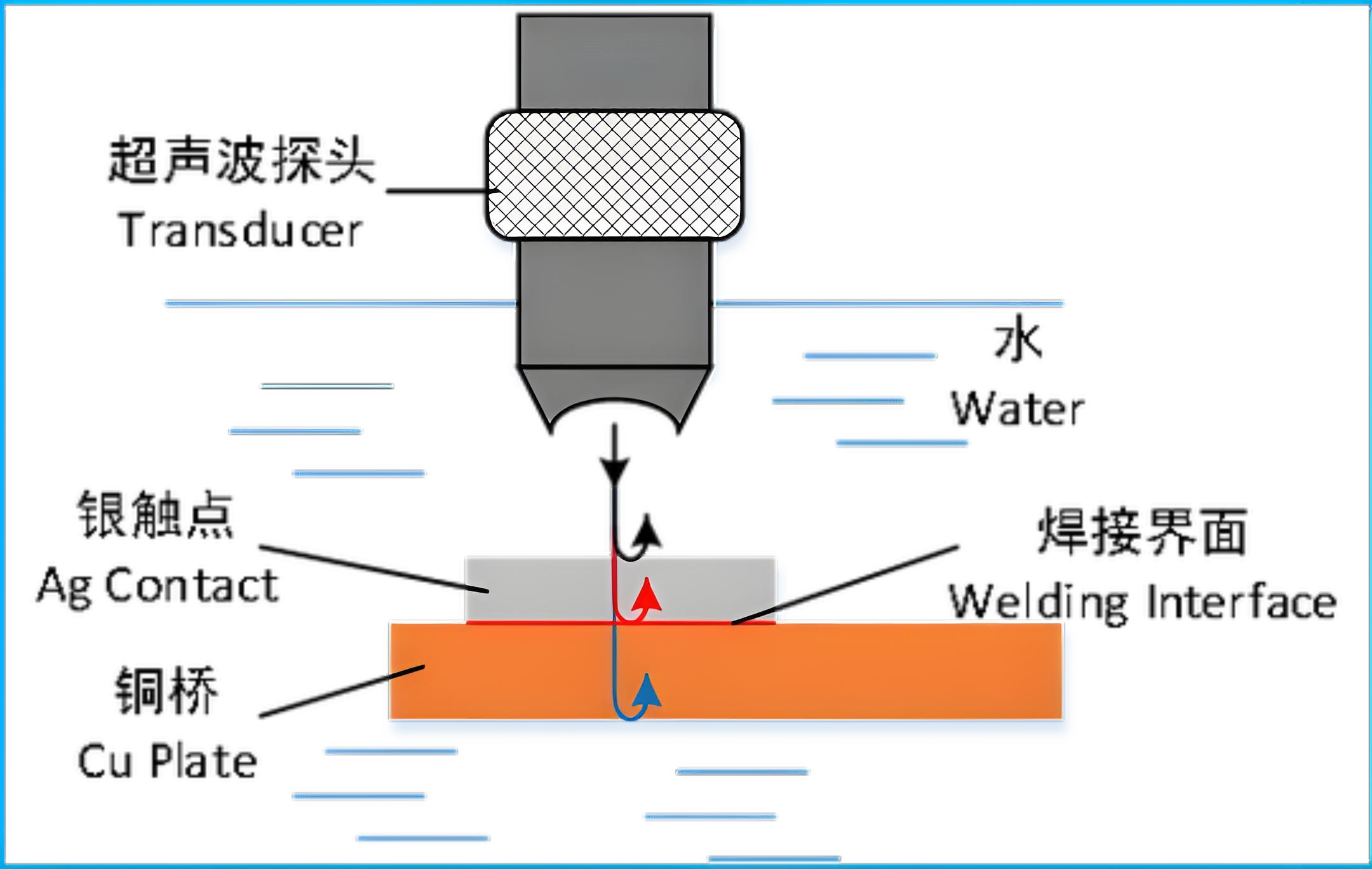

The ultrasonic waves emitted by transducer belong to mechanical waves, which are generated by the mechanical vibration of the ultrasonic transducer wafer. At the interface where two different materials meet, if the acoustic impedance difference is greater than 0.1% and the interface is significantly larger than the wavelength (i.e., a large interface), reflection will occur. When encountering air (such as delamination or void), there will be 100% reflection. Due to the extremely short wavelength used by the Scanning Acoustic Microscope, the ultrasonic waves propagate in a straight line just like light. By sampling the transmitted waves or reflected waves, the Scanning Acoustic Microscope can detect structural changes inside materials or devices based on the changes in the waveform.

By emitting acoustic wave pulses into the interior of the packaged device, the reflection of ultrasonic waves on materials with the same ultrasonic impedance is very weak. However, when transmitting from one material to another, there will be a stronger reflection. The Scanning Acoustic Microscope analyzes the intensity and phase of the reflected waves and constructs A, B, C ultrasonic scanning images. The common modes of the ultrasonic scanning microscope include A-scan, B-scan, C-scan, and tomographic microscopic imaging.

The Scanning Acoustic Microscope operates based on the principle of pulse-echo. A specific high-frequency ultrasonic transducer with a focusing function is used to emit and receive short ultrasonic pulses at a high repetition rate. The ultrasonic waves interact with the sample being tested, and the reflected waves are received and then converted into image signals. The scanning mechanism moves back and forth above the sample, and through the method of point-by-point scanning, the intensity and phase information of the reflected waves at each point of the sample are synchronously recorded in sequence and converted into pixel points with certain gray values. This enables the detection of the internal structure and defects of the material and the formation of a microscopic image of the internal structure of the material. Currently, the highest resolution that the Scanning Acoustic Microscope can achieve is on the micron level.