Application of Scanning Acoustic Microscopy in Defect Inspection of Underfill on PCBA

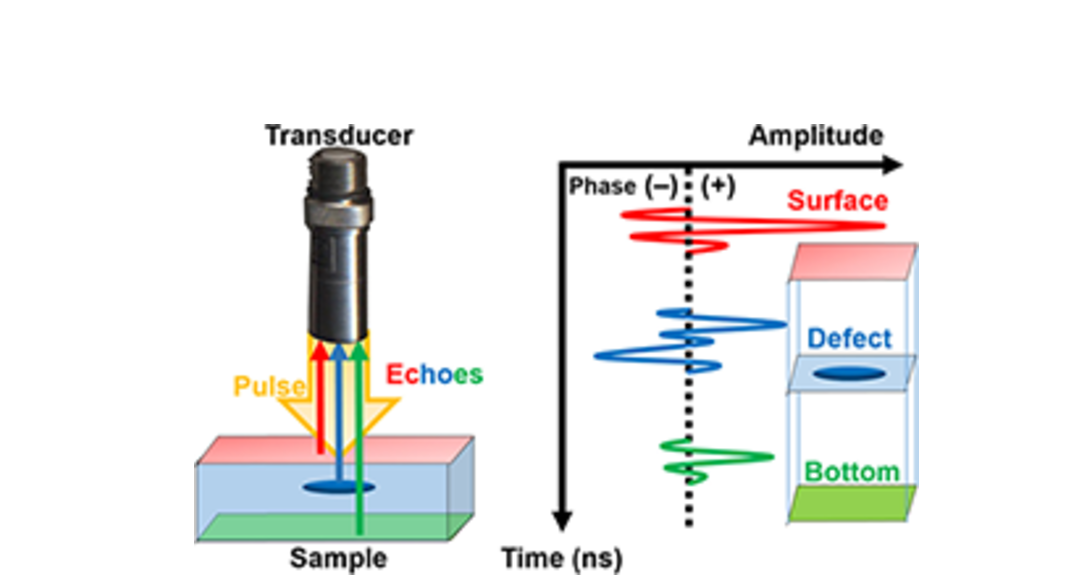

Scanning Acoustic Microscopy (SAM) is a high-precision, non-destructive testing technique that utilizes high-frequency ultrasound to inspect the internal structure of materials. It is particularly well-suited