Scanning Acoustic Microscopes, known as Scanning Acoustic Microscopes (SAM), utilize the differences in acoustic impedance, absorption, and reflection of ultrasonic waves by various materials to detect the internal structure and defects of semiconductors and other components. They are essential for qualitative analysis of components and materials and represent a crucial non-destructive testing method in current nanotechnology research. Ultrasonic waves, or Ultrasound, refer to any sound or vibration with a frequency exceeding the highest threshold audible to the human ear, which is 20 kHz (kilohertz). Typically, when a piezoelectric transducer crystal (often referred to as a crystal) is subjected to a voltage, it deforms under pressure in a direction perpendicular to its surface. Once the voltage disappears, usually within a microsecond, the crystal snaps back, generating a mechanical energy pulse that forms an ultrasonic wave.

Scanning Acoustic Microscopes utilize ultrasonic waves with the following characteristics:

Type: Probes can be categorized into contact, delay line, angle beam, or immersion types based on their functionality. Characteristics of the material being tested, such as surface roughness, temperature, accessibility, location of defects within the material, and inspection speed, all influence the choice of probe type. Typically, ultrasonic scanning microscopes use immersion ultrasonic probes.

Diameter: The diameter refers to the size of the active probe crystal. The crystal is usually housed in a casing slightly larger than itself. Larger diameter probes in ultrasonic scanning microscopes can provide higher signal strength and greater focal length.

Frequency: Frequency is the number of vibration cycles a sound wave completes per second, typically expressed in kilohertz (kHz) or megahertz (MHz). Most industrial ultrasonic testing is conducted within a frequency range of 500 kHz to 20 MHz, so most probes operate within this range. However, commercial probes with frequencies below 50 kHz and above 200 MHz are also available. In ultrasonic scanning microscopes, lower probe frequencies offer greater penetration power, while higher frequencies provide higher resolution and focusing power.

Bandwidth: Bandwidth refers to the portion of the frequency response within a specific amplitude range. In this context, it is important to note that typical NDT probes do not generate sound waves at a purely single frequency but rather within a frequency range centered around the rated frequency value. The industrial standard defines this bandwidth at the -6dB (or half-amplitude) point.

Pulse Duration: Pulse duration refers to the number of wave cycles generated each time the probe is triggered by a pulse. Narrow bandwidth probes generate more wave cycles than wide bandwidth probes. The crystal diameter, base material, electronic tuning, and probe excitation method all affect pulse duration.

Sensitivity: Sensitivity refers to the relationship between the amplitude of the excitation pulse and the amplitude of the echo reflected from a specified target.

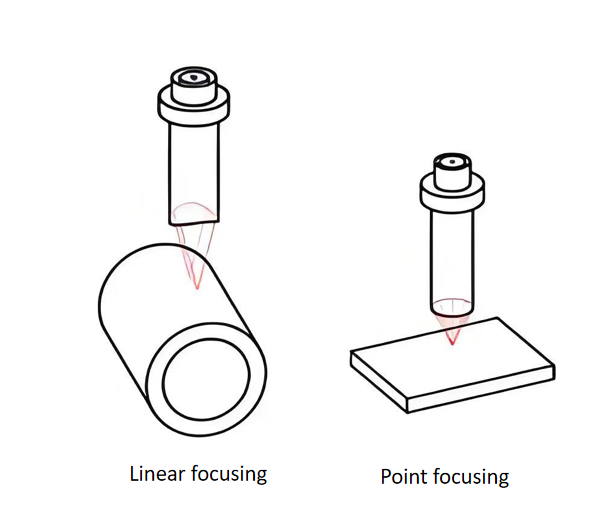

Ultrasonic Beam Characteristics: Ultrasonic waves have high frequencies and strong directionality, also known as beaminess. When the diameter of the ultrasonic transducer, such as a piezoelectric crystal, is much larger than the wavelength of the ultrasonic wave, the ultrasound produced behaves similarly to light. With high frequency and short wavelength, ultrasonic waves, like light waves, can be focused in one direction and can be converged or diverged using appropriate methods. Therefore, ultrasonic beams can refract, reflect, and focus, following the laws of geometric optics. Ultrasonic scanning microscopes use focused ultrasonic waves, relying on the generation of reflected and transmitted wave signals to achieve non-destructive scanning and inspection of the internal structures of materials and devices.

Transmission, Reflection, Refraction, and Focusing of Ultrasonic Waves: Due to their high frequency, ultrasonic waves exhibit phenomena similar to light when they propagate in a directed manner at the interface between two different media, such as transmission, reflection, and refraction. The focusing phenomenon of ultrasonic waves is analogous to that of light. Ultrasonic waves can be converged to a point using focusing devices, thereby increasing the sound intensity by several times or even thousands of times. This significant intensity can be used for many meaningful applications, such as ultrasonic cutting, ultrasonic drilling, ultrasonic polishing, and ultrasonic scanning microscopy.

Absorption and Attenuation of Ultrasonic Waves: As ultrasonic waves propagate through various media, their intensity gradually diminishes with increasing distance due to the absorption of some of their energy by the medium. For the same material, the higher the frequency of the ultrasonic wave, the greater the absorption. Consequently, the higher the resolution of an ultrasonic scanning microscope, the smaller the penetration depth.