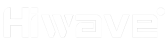

Ultrasound refers to any sound wave or vibration whose frequency exceeds the maximum threshold of 20 kHz (kilohertz) that human ears can hear. Due to its high-frequency characteristics, ultrasound is widely applied in numerous fields such as medicine, industry, and intelligence.

Ultrasonic Wave

Definition: Sound waves with a frequency higher than 20 kHz.

Discipline: Physics_Optics, Acoustics_Acoustics Related

Terms: Sound Wave, Transducer, Mechanical Wave

The sound wave that people are most familiar with is audible sound, which is the sound wave with a frequency ranging from 20 Hz to 20,000 Hz. In the 20th century, with the development of electronics, electro-acoustic transducers were able to generate, receive and utilize sound waves of any frequency, any waveform and almost any intensity. Through electronic devices, sound waves could also be “seen”. In this way, not only the audible sound that ears can hear but also ultrasonic waves with a frequency higher than 20,000 Hz and infrasonic waves with a frequency lower than 20 Hz could be “seen”.

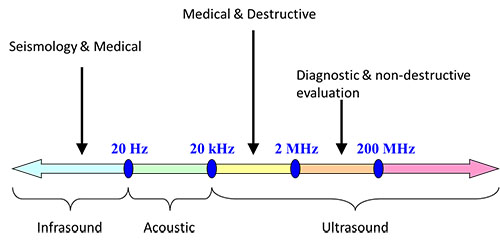

Ultrasonic waves, like audible sound and infrasonic waves, are mechanical waves that propagate in a medium. Due to its short wavelength, ultrasonic waves have many characteristics. Ultrasonic waves are high-frequency sound waves. When propagating in the same medium, as the frequency increases, the energy absorbed by the medium becomes greater. For ultrasonic waves of the same frequency, the propagation distance varies depending on the medium. When ultrasonic waves propagate in gas, liquid and solid, the absorption is strong, relatively weak and weak in turn.

Many animals can emit and receive ultrasonic waves, among which bats are the most representative. They can fly and catch food in the dark by using weak ultrasonic echoes. Because of the good directivity of ultrasonic waves and their long propagation distance in water, people invented sonar, which is often used in underwater navigation.

Due to its short wavelength, ultrasonic waves have the characteristics of good directivity, strong penetrating ability and easy access to more concentrated sound energy. They can be used for detection, speed measurement, welding, lithotripsy, etc. For example, the scanning acoustic microscope can non-contact and non-destructively detect the internal structure and defects of materials or devices. The cavitation effect of ultrasonic waves is often used for cleaning oil stains. Ultrasonic waves not only have a wide range of uses in production but also various applications in daily life. For example, the B-ultrasound (B-mode ultrasonic examination equipment) commonly used in hospitals is used for in vivo examination; some humidifiers commonly used in winter in the north also use ultrasonic waves.

Ultrasonic waves have significant applications in the military, medical, and industrial fields. According to the power level, its applications can be divided into power ultrasonic and inspection ultrasonic. The applications of power ultrasonic include welding, drilling, pulverizing, cleaning, emulsifying, etc. Most of these are ultrasonic devices that only emit but do not receive. Currently, the exact theory of ultrasonic machining is still not fully understood. In the military, inspection ultrasonic is applied in radar positioning and so on. Medical ultrasonic waves can penetrate muscles and soft tissues, so this technique is often used to scan many organs to assist in medical diagnosis and treatment. Obstetric ultrasonic is also commonly used for examinations during pregnancy. Doctors can use ultrasonic imaging to see through the body. However, since ultrasonic waves cannot penetrate bones, although they cause relatively low harm to the human body, they still cannot completely replace X-rays. Typical ultrasonic waves have a frequency of about 2 MHz to 10 MHz, while the Scanning Acoustic Microscope can utilize ultrasonic waves with a frequency as high as GHz to achieve ultra-precision non-destructive testing. Inspection ultrasonic devices have both emission and reception functions.

Hiwave specializes in providing ultrasonic scanning microscopes (USM) for precise non-destructive testing in semiconductors and electronics.