How to Detect Internal Defects in Silver Contacts

views:452

author:admin

source:Hiwave

time:2025-08-20

catogory:Industry News

Silver contacts are widely used in various electrical and electronic devices such as relays, switches, and circuit breakers due to their excellent electrical and the……

Silver contacts are widely used in various electrical and electronic devices such as relays, switches, and circuit breakers due to their excellent electrical and thermal conductivity, as well as stable chemical properties in diverse environments. They are critical components ensuring reliable circuit connection and disconnection. The internal quality of silver contacts directly affects the safety and service life of the entire electrical system. Traditional inspection methods (such as visual inspection and X-ray) have limitations in detecting internal micro-defects. Scanning Acoustic Microscopy (SAM), as a non-destructive, high-resolution internal imaging technique, has become a powerful tool for detecting internal structural defects (such as cracks, delamination, porosity, and inclusions) in silver contacts.

Introduction

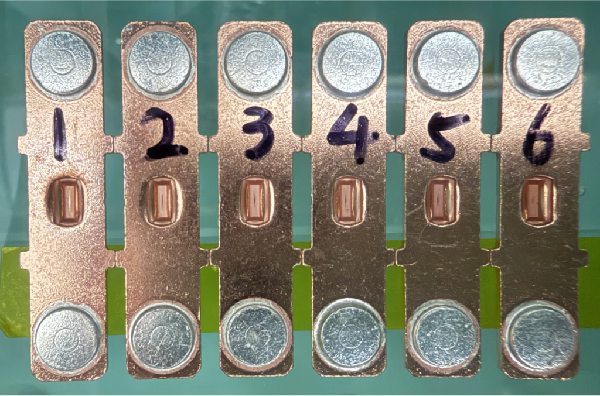

Silver contacts are typically bonded to substrates (such as copper alloys) via methods like welding, sintering, or mechanical crimping. During manufacturing (e.g., stamping, welding, sintering) or subsequent use, minor defects are prone to occur within the contact or at the interface due to factors such as material stress, thermal cycling, and mechanical shock. If not detected in time, these defects can lead to increased contact resistance, localized overheating, intensified arc erosion, and ultimately contact failure, causing equipment malfunctions or even safety incidents. Therefore, reliable internal non-destructive testing of silver contacts is crucial.

Working Principle of Scanning Acoustic Microscopy (SAM)

SAM uses high-frequency ultrasound (typically ranging from 10 MHz to 230 MHz or higher) as a probe to penetrate the sample and receive ultrasonic signals reflected from different internal interfaces. Its basic working principle is as follows:

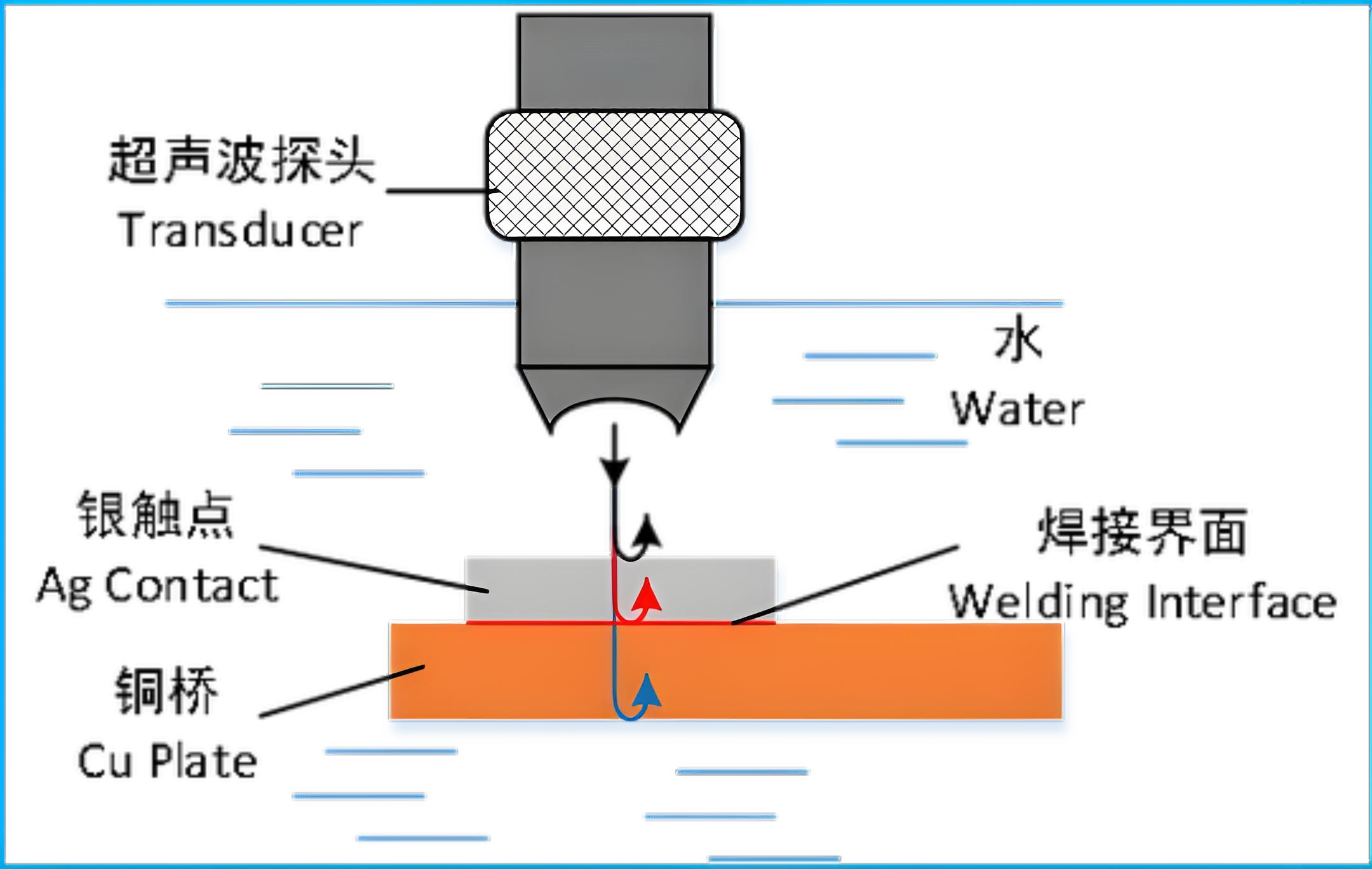

Ultrasonic Emission and Reception: A piezoelectric transducer (probe) generates high-frequency ultrasonic pulses, which enter the sample through a coupling medium (usually deionized water).

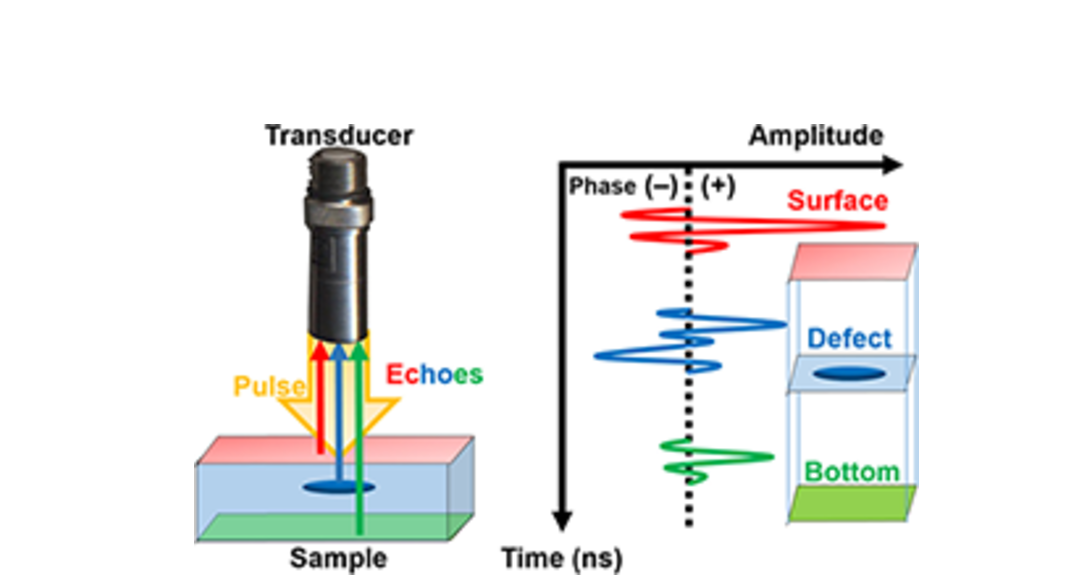

Acoustic Impedance Differences and Reflection: As the ultrasonic wave propagates within the sample, it encounters interfaces with different acoustic impedances (e.g., solid/air interface, solid/solid interface, internal cracks or pores), resulting in reflection and transmission. The greater the difference in acoustic impedance, the stronger the reflected echo.

Signal Acquisition and Imaging: The transducer receives echoes reflected from interfaces at different depths. By precisely controlling the probe’s scan in the X-Y plane and recording the amplitude (A-Scan) or phase information of the echoes within a specific time window (corresponding to a specific depth) at each scanning point, two-dimensional (B-Scan, C-Scan) or three-dimensional (3D) images of the sample’s internal structure at a specific depth or throughout its volume can be constructed.

C-Scan (Planar Image): The most commonly used mode, displaying the defect distribution on a specific depth plane within the sample. Strongly reflective interfaces (such as air gaps, cracks) appear as bright areas (high echo amplitude), while homogeneous materials or weakly reflective interfaces appear as dark areas.

Application of SAM in Silver Contact Inspection

SAM technology is particularly suitable for detecting the following common internal defects in silver contacts:

Interface Delamination:

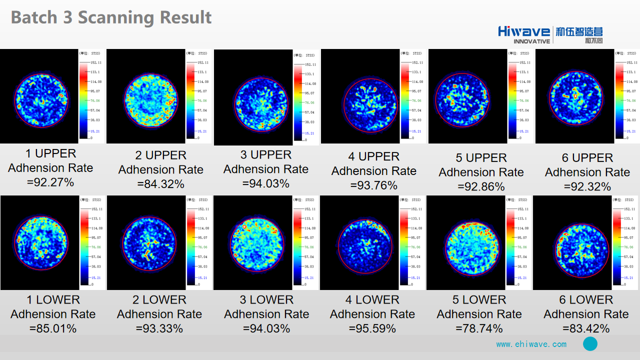

SAM Detection: The difference in acoustic impedance between air and metal is extremely large, so interface delamination produces a very strong ultrasonic reflection, clearly appearing as bright areas in the C-Scan image. The shape and size of these areas directly reflect the extent of delamination. SAM can effectively distinguish between good metallurgical bonding (weak reflection, dark areas) and delamination (strong reflection, bright areas).

Internal Cracks:

SAM Detection: Cracks are typically filled with air or vacuum, forming a strongly reflective interface with the metal. SAM can clearly image the crack’s orientation, length, and depth, even detecting very fine cracks.

Porosity and Voids:

SAM Detection: Porosity and voids also appear as strong reflection points or regions. By analyzing the density and size of bright spots in the C-Scan image, the material’s density can be assessed.

Inclusions:

SAM Detection: Inclusions have different acoustic impedance from the silver matrix, generating reflection signals. Depending on the nature of the inclusion (e.g., oxide, ceramic), the reflection intensity varies, appearing as abnormal bright or dark spots in the SAM image.

Welding/Sintering Quality Assessment:

SAM Detection: The C-Scan image allows direct observation of the acoustic response across the entire bonding interface. A uniform dark background indicates good bonding, while irregular bright spots, lines, or large bright areas indicate defects such as delamination, incomplete welding, insufficient or excessive solder.

Scanning Acoustic Microscopy (SAM) is an indispensable advanced non-destructive testing technology for detecting internal defects in silver contacts. It can effectively and accurately identify and evaluate critical defects such as delamination, cracks, and porosity, providing strong support for quality control, failure analysis, and reliability assessment. With continuous improvements in probe technology, signal processing algorithms, and automation, the application of SAM in the inspection of silver contacts and other electronic components will become even more extensive and profound, playing a vital role in ensuring the safe and reliable operation of electrical systems.