Scanning Acoustic Microscope for Polycrystalline Diamond Compact(PDC)

views:641

author:admin

source:Hiwave

time:2024-12-19

catogory:Industry News

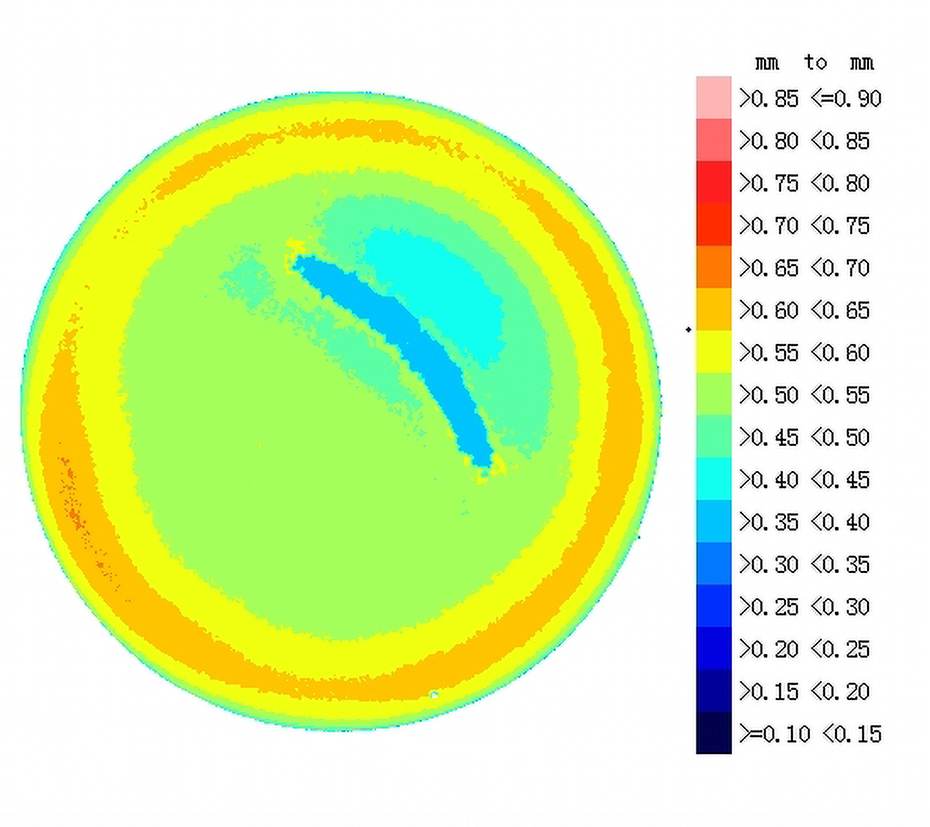

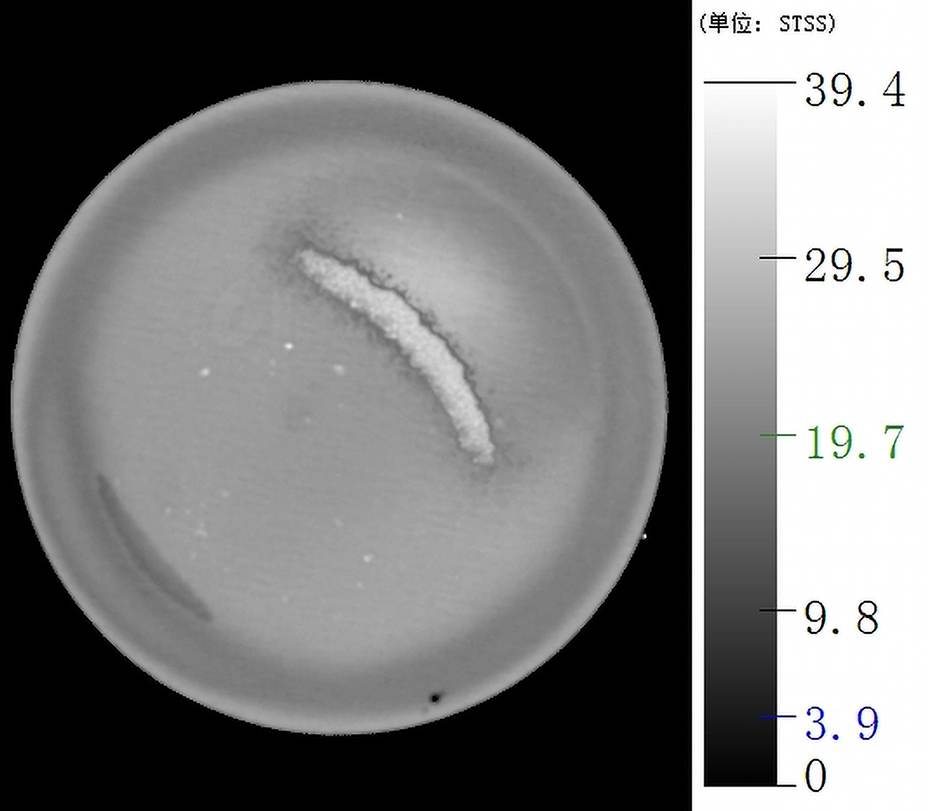

Polycrystalline diamond compacts are widely used in various industries due to their excellent hardness, wear resistance, and thermal conductivity, mainly in situatio……