Resolution and Focal Length of Scanning Acoustic Microscope

views:927

author:admin

source:Hiwave

time:2024-12-20

catogory:Frequently Asked Questions

With the development of semiconductor materials and devices, the diversification, miniaturization and integration of packaging forms have put forward new requirements for the resolution and penetrat……

With the development of semiconductor materials and devices, the diversification, miniaturization and integration of packaging forms have put forward new requirements for the resolution and penetration depth of scanning acoustic microscopes. The core of the machine is ultrasonic transducers.

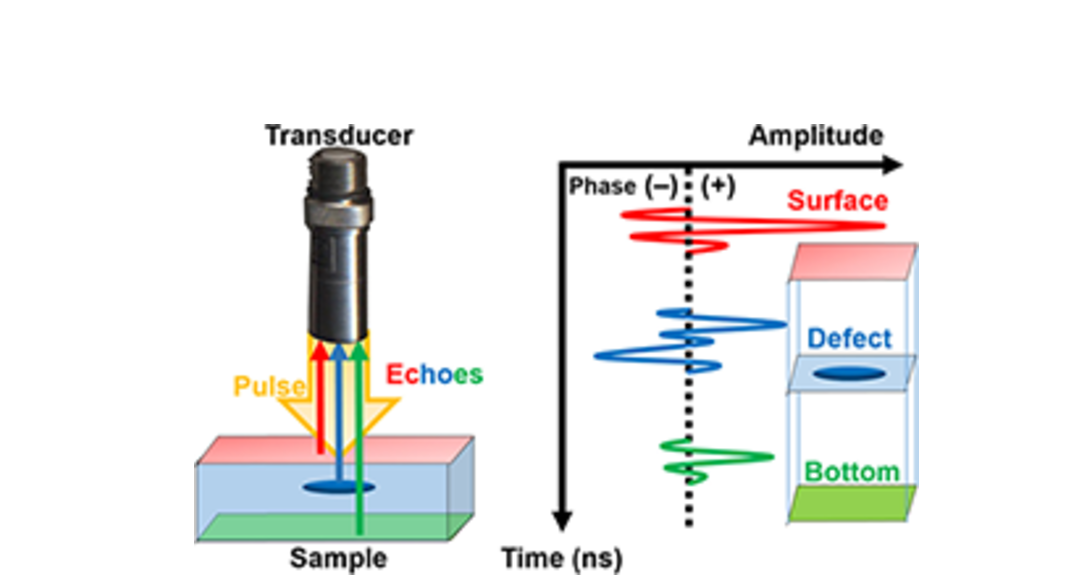

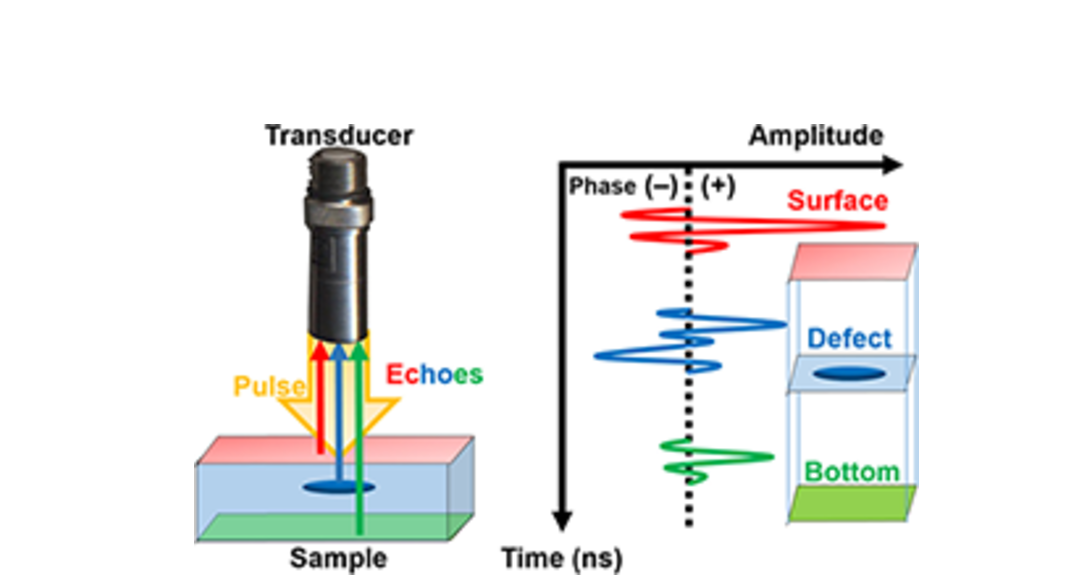

Transducer can generate ultrasonic pulses under the stimulation of radio frequency signals. These ultrasonic signals are focused on the components or materials under test. When ultrasonic waves encounter different material interfaces or defects, they will be reflected. The reflected ultrasonic waves are converted into electrical signals by ultrasonic transducers and collected into computers for analysis, processing and graphical display.

transducer

transducer

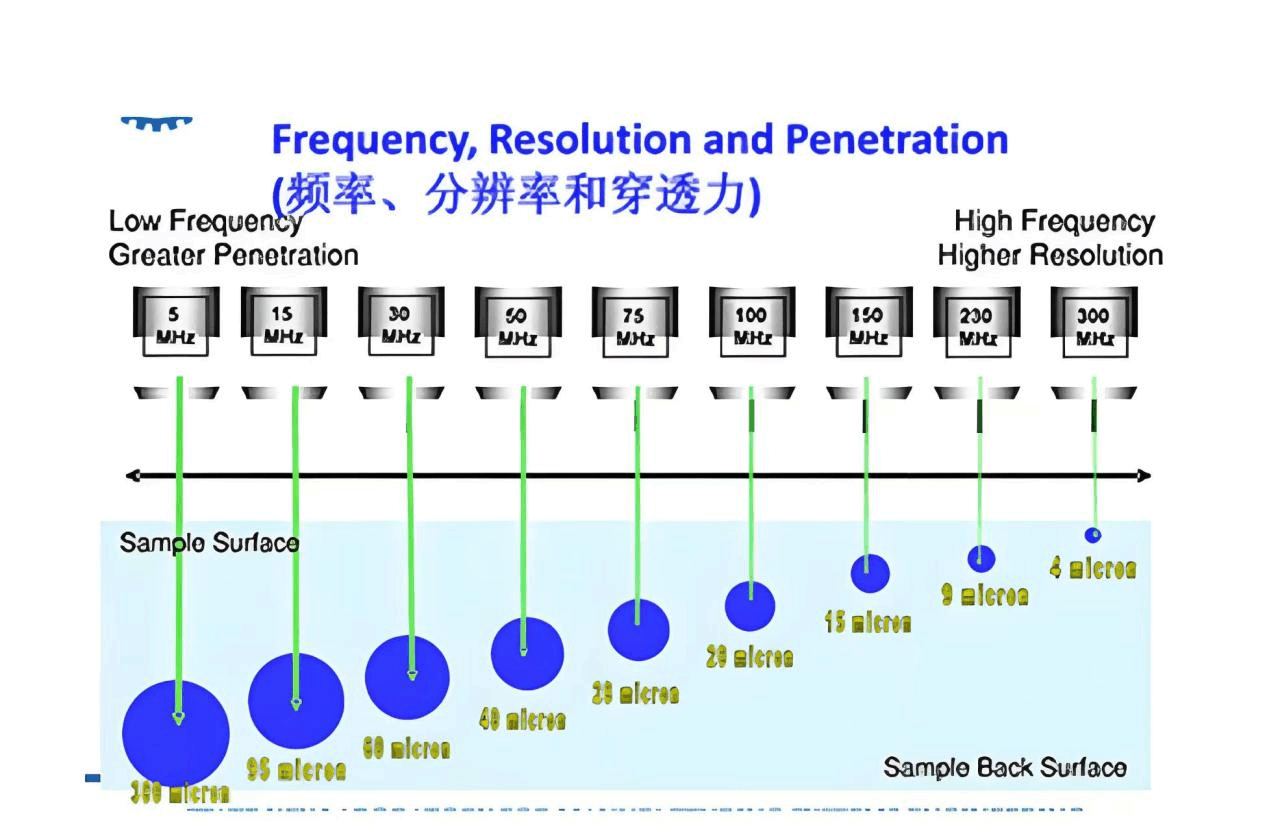

Relationship between probe frequency and resolution

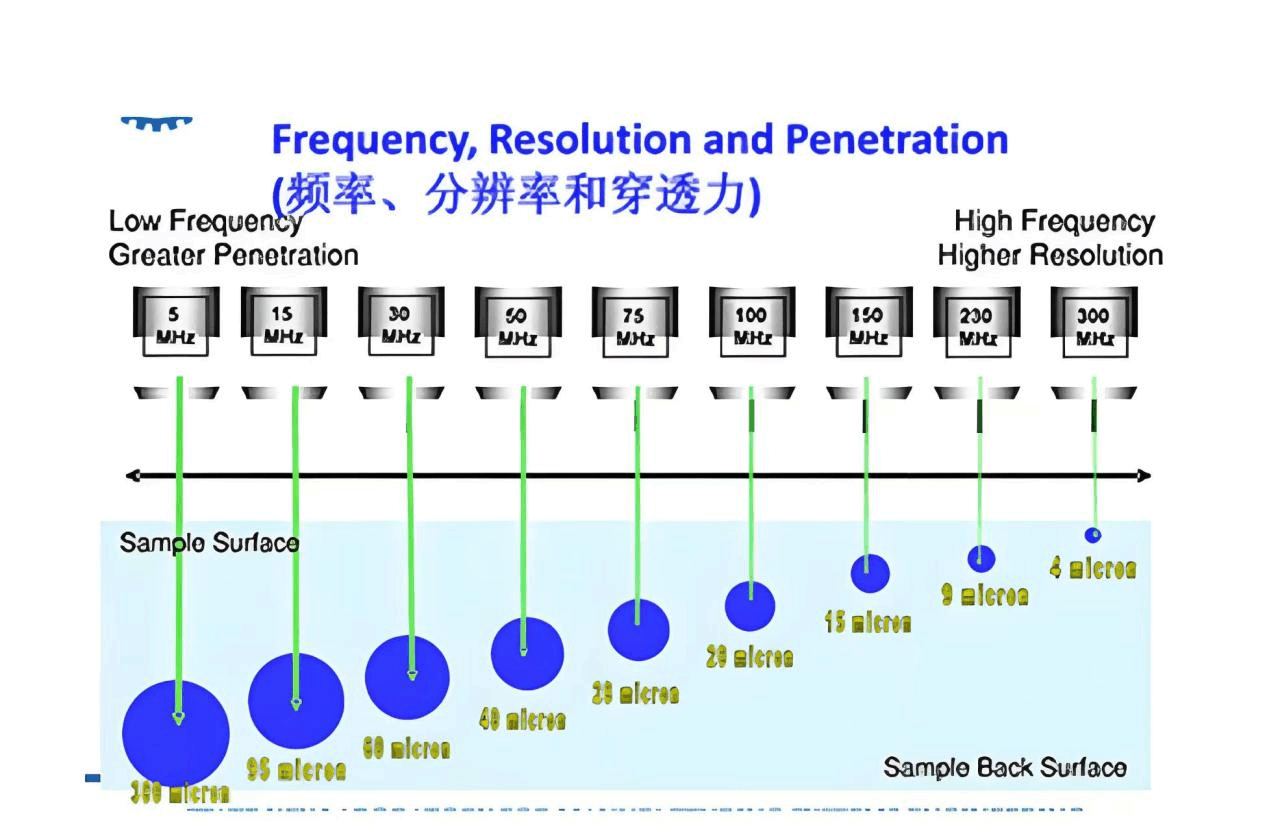

As the core component of scanning acoustic microscope, the performance of ultrasonic transducer is crucial. The main technical parameters and performance indicators include piezoelectric chip size, ultrasonic frequency, probe focal length, frequency bandwidth, etc. In general, the higher the frequency of ultrasonic transducer, the higher the resolution of ultrasonic scanning microscope, the stronger the ability to detect tiny defects, the smaller the penetration depth , and the slower the detection speed . Therefore, for thicker samples, ultrasonic scanning microscopes usually use ultrasonic probes with relatively low frequencies to obtain higher penetration capabilities.

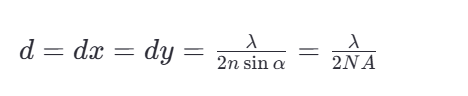

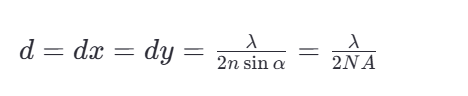

d: Resolution

dx and dy: The resolution in the x and y directions.

λ : wavelength

n: refractive index of the medium

α: Angle of incidence

NA: Numerical Aperture

Other factors affecting resolution

The resolution of ultrasonic scanning microscope is mainly affected by the frequency of the probe. The theoretical resolution can reach 1/2-1/3 of the wavelength L of ultrasonic wave inside the material . L=V/F , V represents the longitudinal propagation speed of ultrasonic wave inside the material , and F represents the frequency of ultrasonic probe . It can be seen that the higher the frequency of the probe, the higher the resolution of ultrasonic scanning microscope and the stronger the detection ability of tiny defects. At the same time, the resolution of ultrasonic scanning microscope is also affected by the longitudinal propagation speed of ultrasonic wave inside the material, the focal length of the probe, and the diameter of the focal sound spot . Therefore, for material devices with different characteristics, different focal lengths, and different focal sound spot diameters, the actual performance of the resolution of ultrasonic scanning microscope is also different.

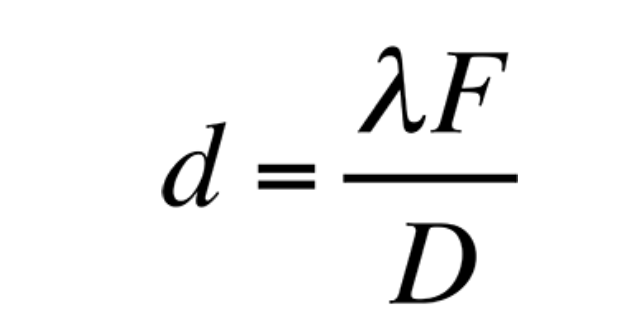

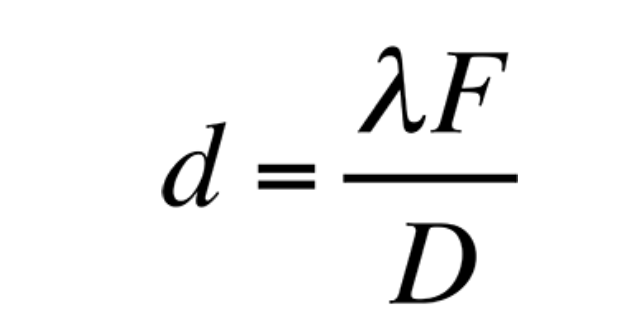

Relationship between wavelength, frequency, focal length and diameter

Relationship between probe frequency and focal length

The probe has a very important influence on the detection effect of scanning acoustic microscope. For detection imaging, the smaller the focal beam width, the clearer the scanned image, that is, the higher the lateral resolution. Generally speaking, the higher the frequency, the narrower the focal beam width, and the higher the lateral imaging accuracy .

Therefore, when ultrasonic scanning microscope detection is performed, it is generally hoped that the frequency of the transducer used is as high as possible. However, when the frequency of the ultrasonic scanning microscope transducer is increased, the attenuation of the sound intensity will increase rapidly.And its penetration ability will drop sharply. In addition, the higher the frequency, the worse the signal-to-noise ratio, and the echo signal is often submerged in the noise signal. The scanned image will become blurred due to the increase in noise points .

As one of the main technologies of non-destructive testing, scanning acoustic microscope testing equipment will play an increasingly important role in the future industrial chain. As an important technical indicator of ultrasonic scanning microscope, detection resolution will also continue to break through and develop.

transducer

transducer